Singapore 349245

Roadmap

Automated systems

Play safe and benefit from our many years of know-how! The degree of automation of a kitchen depends not only on the type and quantity of the items to be washed. Nearly every size of kitchen offers rationalized workflows, which increase profitability and work relieve for your staff.

At the Research and Development Center in Offenburg, our engineers are constantly working on new ideas based on our over 100 years of know-how. With countless innovative features, we show you the diversity of the spectrum, how HOBART is able to implement sophisticated technology into meaningful concepts and solutions, so that you can realize savings in operating costs and achieve even more process reliability.

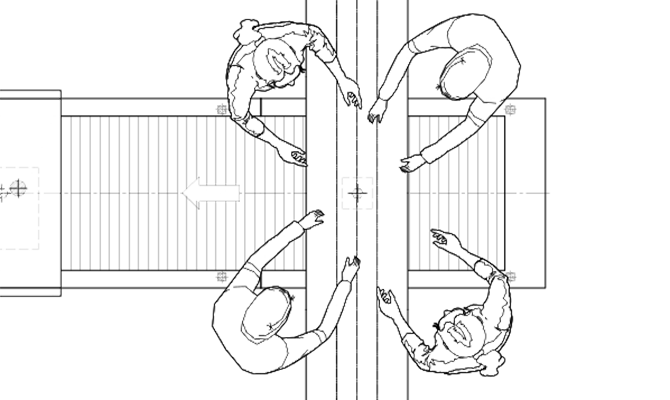

Lowered intake of flight-type dishwashers

It is not only the capacity of the dishwasher that must be laid out for a high wash ware volume. The performance of the dishwashing staff is limited, too. Frequently, the classical two working positions at the intake of a flight-type dishwasher prove insufficient.

HOBART uses lowered loading areas to provide up to four working positions at the intake of a flight-type dishwasher. This considerably increases the capacity of the washing organisation.

CLIMATE-PRO energy saving system

Innovation meets economy and energy efficiency

You can save up to 22 kWh with the novel energy system CLIMATE-PRO.

OUR CLEVER SOLUTION FOR YOU: The thermal energy contained in the exhaust air is 100% regenerated by means of state-of-the-art technology and returned to the rinse process. This not only helps you to reduce the energy consumption of your machine but also to save on the related operating costs.

BY THE WAY: As a result of constantly low exhaust air temperatures, the room climate is improved at the same time.

Efficiency concept

clever technology paired with efficient use

Saving on operating costs made easy: The innovative efficiency concept lowers your costs, avoids energy losses and reduces the exhaust air volume. Eliminates the need for direct connection to an on-site exhaust hood.

CLEANING MANAGEMENT

A good cleaning result depends on many parameters. The innovative cleaning management optimally combines mechanics, circulation output, water distribution, chemical agents, time, and contact area. As a result, this innovative cleaning management achieves best results and at the same time provides for

- additional energy savings,

- reduced connected loads,

- reduced heat losses

- and improved detergent action.

Exhaust air management

As the new cleaning management reduces water circulation, this has an immediate effect on the formation of waste steam.

BECAUSE: Less waste steam means less exhaust air. The reduced exhaust air volume eliminates the need for direct connection to an on-site ventilation system.

Drying management

The drying zone has been optimised for direct guidance of the air flows and a more efficient use of energy. As a result, the drying air is not indiscriminately blown out, but is systematically used where it is needed.

TOP-TEMP energy management

prevents energy losses before they arise

Reduce the energy loss of your dishwashing system by up to 30% with the patented and standard energy management.

In this system, the hot machine zones are enclosed by the cooler zones such as pre-wash and drying. The resulting temperature curtain ensures that air exchange can only take place within the machine. The PREMAX is characterised by a special temperature profile and exploits this principle in an optimum manner.

Automatic separation system

only available for automatic systems

The automatic separation system sits upstream of an automatic dishwasher system. It performs the activities that are performed manually by the dishwashing staff in a classical semi-automatic washing organisation.

The automatic separation system separates all wash ware components, prewashes them and clocks them into the corresponding tracks of the subsequent flight-type dishwashers. The integrated preliminary cleaning system is additionally with an additional separate soil removal unit.

Fire protection doors/

conveyor system closures

The round-belt conveyors that are used for conveying the trays frequently run through fire protection sections. In such a case, special conveyor system closures are required that, for example, can seal off the dining room from the scullery in the event of a fire, thus preventing the fire from spreading.

Conveyor system closures (FAA) are available with full stainless-steel cladding for separate conveyor systems (closing from bottom to top), for continuous conveyor systems (closing from top to bottom) and in special versions are equipped with a horizontal closing device underneath the ceiling. The control systems of conveying and fire protection systems are connected with each other. In the event of a fire alarm, the drive motor of the belt conveyor is disconnected and fed with emergency power to be able to empty the belt conveyor when the fire protection door closes.

Cutlery lift-off magnet

The cutlery lift-off magnet is provided to automatically lift off and remove cutlery. It is mainly used in combination with semi-automatic and automatic dishwasher systems. The permanent magnet in the inner drum of the completely encapsulated cutlery lift-off magnet lifts the cutlery off the tray and transports it gently on the plastic sliding lining of the stationary outer drum. Next, the cutlery is fed automatically via a chute/slide that is installed on the magnet to the cutlery track of a tray and cutlery dishwasher. The cutlery lift-off magnet may also be used in smaller washing organisations to lift cutlery automatically off the trays and to drop it via the chute into a cutlery basket or a cutlery dip tank underneath.

Easy cleaning

The stationary outer drum serving as a sliding surface mostly prevents the entry of dirt into the inside of the magnet.

Automatic plate unstacking

available for semi-automatic and automatic dishwasher systems

The automatic plate unstacking device connects to the outlet side of a flight-type dishwasher. The plates are transferred automatically from the separate plate track of the flight-type dishwashers to the downstream plate unstacking device.

Automatic plate unstacking devices exist in different versions. For example, as an automatic stacking device with one or two tubular dispensers or as a stacking device onto a conveyor belt.